The site of the Science and Industry Museum in Manchester is, as the official blurb puts it without undue hyperbole, a place that “changed the world”. The first purpose-built passenger railway, the Liverpool and Manchester, started running from here in 1830, and over the next century or more it helped fuel the industrial and commercial beast of the city around it, its trains running in and out to feed factories with cotton, and people with imported food. It is, according to the former Science Museum director Neil Cossons, the “Stonehenge of the Industrial Revolution”.

Now it’s a 2.6-hectare (6.5-acre) zone of heritage and open space, standing amid the real estate explosion of modern Manchester, whose shiny towers pop up in the background. Iron and brick structures, originally arranged according to the hard functional logic of gradients and track radiuses, are honoured with Grade I and Grade II Iistings. Layouts dictated by the needs of machines are gradually being turned over to gentler uses, as open spaces accessible to the growing population of central Manchester. The museum, first installed here in 1983, is in the middle of a comprehensive makeover of the whole site, planned for completion in time for the bicentenary of the railway in 2030.

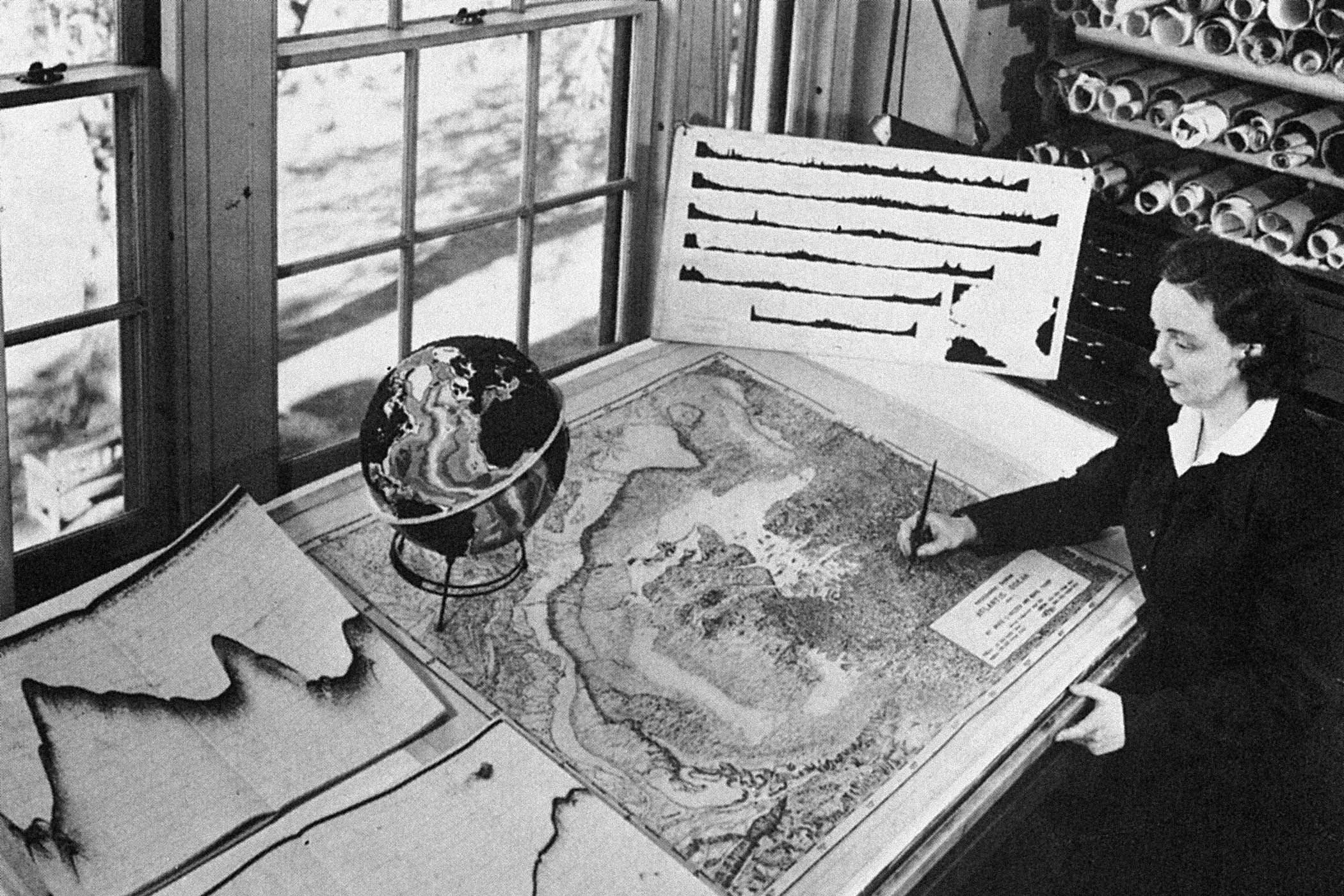

In the middle of it stands the Power Hall, a 108-metre-long (about 355ft) shipping shed where, from 1855, goods trains were once unloaded by men and cranes. It now houses a whirling, spinning, chuntering array of machines that previously performed tasks as diverse as powering hundreds of looms in a Rochdale mill, a dough mixer in a bakery, church organs and chip shops.

There are the kind of engines that stand still in a factory, and locomotives: a grey, 2 8-wheel monster that hauled long coal trains across the hilly terrain of South Africa; and a tank engine that pulled holiday trains on the Isle of Man, now partly cut away so you can see its inner workings. There’s a replica of the Planet, a tall-chimneyed yellow teapot of a vehicle that, when it ran on the newly opened Liverpool and Manchester railway, was cutting-edge technology.

Skilled workers tended the metal beasts, alert to any change of tone or beat

Skilled workers tended the metal beasts, alert to any change of tone or beat

Most were powered by steam, some by gas or oil or electricity, and there’s a pumping engine from Manchester’s Victorian hydraulic power system that, until 1972, lifted grain sacks in warehouses and safety curtains in theatres with pressurised water run through pipes under the city’s streets.

Almost all were made in or near Manchester, many of them rescued by enthusiasts from the once proud businesses that ran them when they fell victim to new technologies and overseas competition in the second half of the last century. Many are kept running by the museum, so you can see and hear their different speeds and rhythms, and smell their oil.

This week a rejuvenated version of this temple of manufacture reopens as Power Hall: the Andrew Law Gallery, named after a Manchester-raised hedge fund manager whose foundation has helped fund the £18.9m cost of the project. It’s an undertaking where a problem – the shed’s leaking roof needed fixing – was made into an opportunity, which was to present the industrial ballet of the engines better than ever before.

There was also a wish – superficially oxymoronic – to make this commemoration of fossil-fuel machinery, with the help of the engineers Max Fordham, as sustainable as can be. For if, as the museum says, these machines helped make the modern world, that includes pollution and the climate crisis, as well as mass-produced clothing. Factories ran off arrays of boilers that each consumed about three tonnes of coal – the weight of a male white rhinoceros – every day. Average life expectancy in Manchester in the 1850s was 31, partly as a result of respiratory diseases caused by all the smoke.

Then again, science and industry move on, and the ingenuity that once went into steam engines now goes into less damaging alternatives. So the new Power Hall is run off a heat pump that draws its energy from an aquifer 90 metres below ground. The old machines are now powered by steam heated from this source, and the three-dimensional labyrinth of silvery pipes and boilers that help to make this happen is on public view – an exhibit in itself.

Newsletters

Choose the newsletters you want to receive

View more

For information about how The Observer protects your data, read our Privacy Policy

The design of the renewed hall, by the architects Carmody Groarke and the exhibition designers Studio Mutt, is about standing back and letting both the machines and the original structure speak for themselves. The roof has been insulated, but not so you’d notice, and there are some discreet displays of information and backlit photographs that put the exhibits in context. Metalwork, timber and paving are realised in shades of grey that direct attention back towards the historical material.

There’s a desire to tell the human stories around the engines: the thousands of jobs that relied on their smooth running; of the skilled workers who drew the designs and those who tended the metal beasts, alert to any change of tone or beat that might indicate trouble. Attention is paid to the dark side of the industry, to the lives of the enslaved people who picked the cotton, and to the exploited and underpaid workers who from their early teens helped make it into fabrics.

But it’s the engines that dominate, not least because they are the most compelling exhibits in the museum’s collection. The power that went into them is still imposing after all these years, and they have the fascination that comes with wearing their ingenuity on the outside. Questions of their cruelty and of their benefits are here left unresolved. As with a Roman amphitheatre, you are left to contemplate their might and the atrocities connected with them side by side.

Photographs by Federico Farinatti, Lee McLean/PA